- Language

-

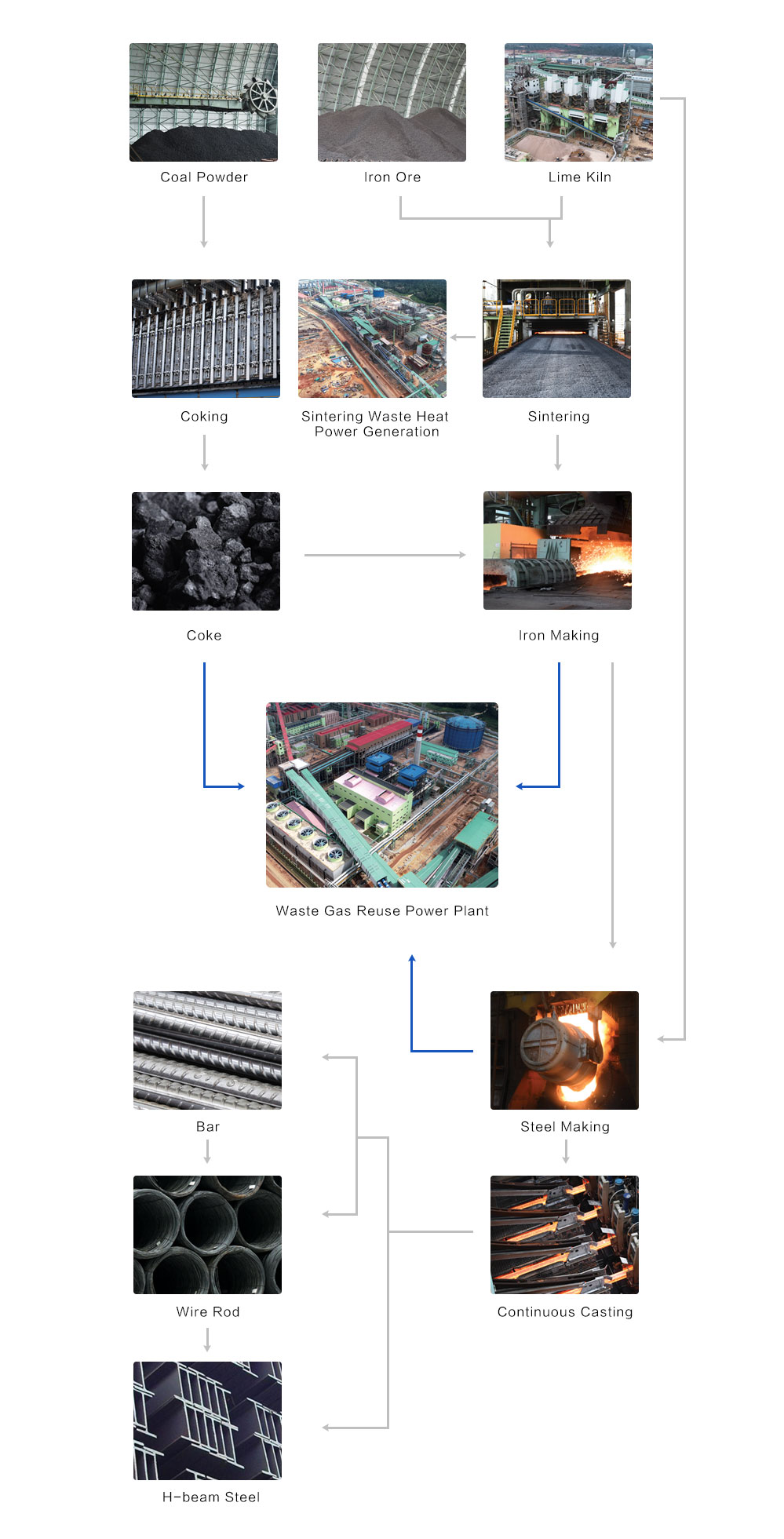

Achieve comprehensive competitiveness through process optimization, energy efficiency and consumption reduction

Recycling of production waste water after treatment

Domestic sewage is treated through septic tank (B type) and discharged with rainwater

Three outlets and three buffer pools are set up in the plant (to control the flow rate of the external discharge)

Reduce the material loss for more than 80%, save the increasingly usage of raw materials resources;

Reduce for more than 90% of particulate dust, improving the environment, practicing people-oriented, promoting economic, social harmonious and sustainable development.

Adopt mature and advanced equipment and facilities for dust removal and desulfurization

Most pollutants are controlled in accordance with Chinas most stringent emission standards

The emission concentration is much lower than the current Malaysian environmental emission standards.

Concrete with water granulated slag powder is stronger than ordinary cement in terms of strength, sulfate attack resistance, chloride ion resistance, adhesiveness, cohesiveness and anti – segregation performance.

Slag: Magnetic separation powder and tailings products. Slag steel and magnetic separation powder are returned to steelmaking or sintering, and tailings are returned to sintering proportioning or sold to building materials industry.

Noise control: Rational layout, selection of low noise equipment, apply corresponding noise reduction, sound absorption and sound insulation measures.

Solid waste: The comprehensive utilization of solid waste in the whole plant is relatively high. Achieve “zero” emission except a small amount of tailings stockpiling.